3D PRINTING TIPS

Things I have learned 3D Printing over 4 Years

Written by Steve Foreman, 5th November 2024

After printing hundreds of models over the years in an attempt to get perfectly working models for my comic book characters, I have learnt a lot of things which I wish someone had shared with me at the beginning. However, because I started 3D printing almost as soon as I could, there was wasn't as much information available then as there is now in this area. Here are some of my tips in model creation to get good prints:

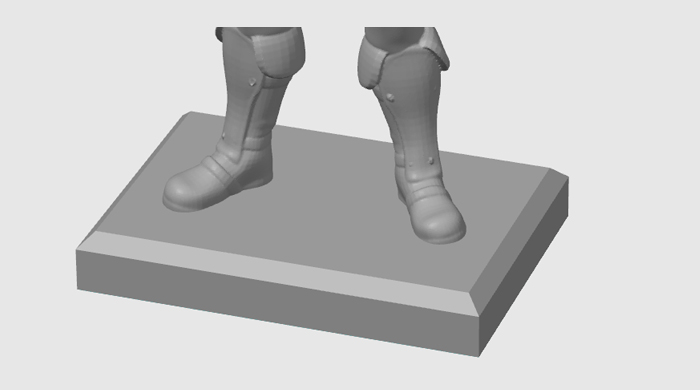

Uniform Toy Model Bases & Stands

Having a good solid base for all models is key in them being well supported so they can freely stand. It may seem obvious but a model may be top heavy. I normally aim for a model to have a 10mm thick base based on the specific size of model I am printing with solid links between the legs of the model and the base.

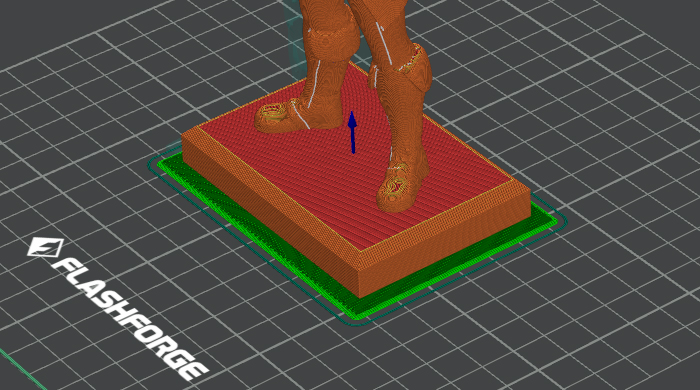

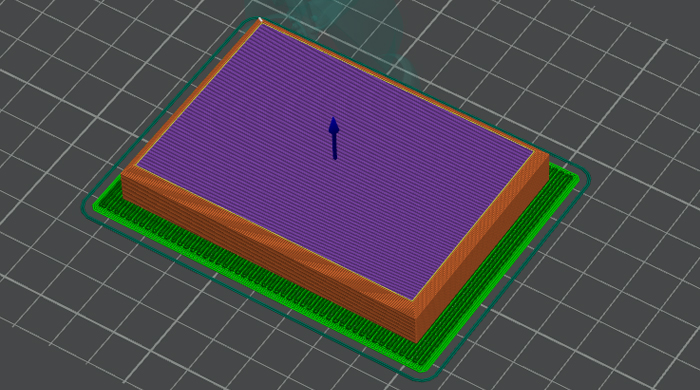

Solid 3D Printer Base Plate Adhesion

Although it may be an underlying issue with the printer bed heat and air temperature (or other factors) I have found having a 5 layer base gives great results in terms of reducing the likelihood of a model breaking apart during a print and also for models using tree supports it really binds the supports in well. Also on some earlier models I got warping on the stands and doing this removed that completely.

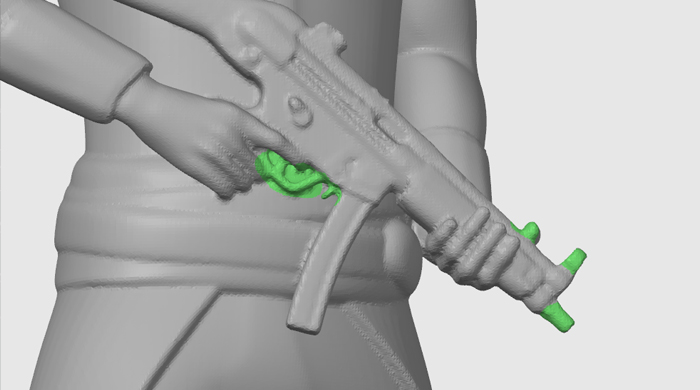

Ensure 3D Prints aren't too thin

Something obvious in hindsight is the scale of model relative to their print size. So, if a model has a very very thin part when printing at a certain size, it will be a weakness in the final model. I have had this problem with wing tips and also the thickness of some parts but it's also to do with how you 3D print something, as you can create a weakness based on the orientation of print on the model.

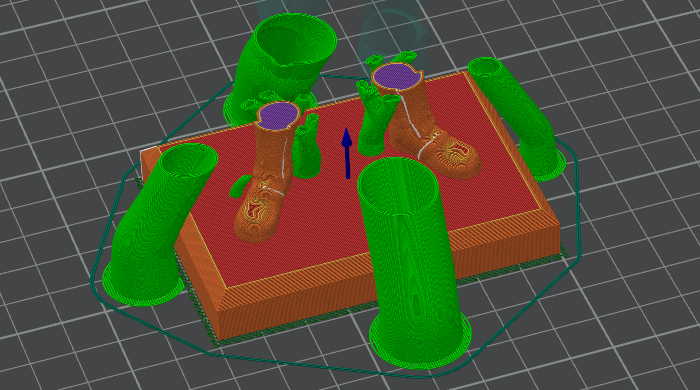

Use Tree 3D Print Supports

One of the greatest developments I think in 3D printing (except for auto levelling!) is tree supports. These are fantastic because they only support the models in specific places rather than all over, which makes removing the excess supports a breeze compared to traditional supports and also you can manually add in supports for any fiddly parts. I would always use the layer scale and look at how a whole model prints, you can often see weaknesses where a part isn't supported well enough - which is fine if that section is connected to another quite quickly, but if it's exposed for 2 hours on an 8-hour print, my experience is 99% of the time it will break, especially if not at 100% infill.

Use 100% PLA infill

I used to print earlier models using as little infill as possible, mainly because the first Crealty Ender 3 printer I had was so slow that it was really just a case of wanting to get the whole thing printed in as short a time as possible. The problem with this is that you often want the infill to add to the weight and quality of a finished model. I now almost only ever print with 100% infill. Sometimes it’s also actually quicker than printing at 70%+ infill because the nozzle has to make the movements between areas anyway.

You can see videos of all my 3D character toy model prints on my Instagram channel @lordofthedragons_, see the link at the bottom of this page for more information.

The World

Learn about the world in which the Lord of the Dragons characters live. Vast forests cover the planet with occassional huge marble Citadels and the remains of humanities once great cities.

Read more

The Characters

Learn about the characters that make the Lord of the Dragons World. Humans who are just trying to survive, green skinned dragons who live in the Citadels and the red skinned dragons who mainly occupy what remains of the old human cities.

Read more